ELECTRONIC MANUFACTURING SERVICES

Leveraging ACTIA’s Global Experience, Knowledge, and Capabilities we can handle simple PCBA to complex Box Builds

- Prototyping

- NPI and ramp up

- Steady State Production Low , Medium, or High volume

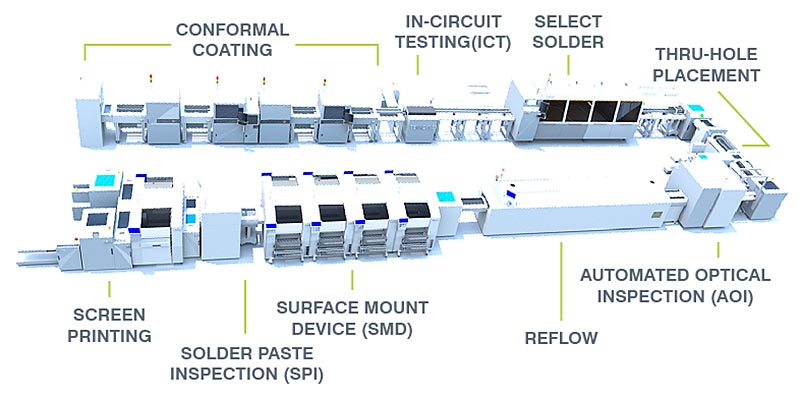

- In Line AOI

- Programing

- SMT; PTH; mixed-technology

- BGA & micro-BGA, fine and ultra-fine pitch; 0201’s. and X-Ray available.

Let ACTIA take you beyond PCBA manufacturing by utilizing our sub assembly and box build capabilities. We can add value in all phases of your product transformation.

|

Mechanical Assembly – Placement of parts in an enclosure |

|

Electro- Mechanical Assembly – Installation of fans, cables, harnesses, and passive components. Building the box with minimal wiring and testing |

|

Electronic Enclosure Assembly – All components fully wired and tested. Installation of intelligent power supplies, complex cable assemblies, backplanes, and thermal controls |

|

Active Cards and Software – Final hardware, software, and other components installed for final testing. Installation of active cards and software with testing |

|

Box Build and Drop Ship – Final configuration and testing of finished products. Logistics to either OEMs or end-customers |