ACTIA KNOW HOW

ACTIA Electronics has been providing end-to-end, turn-key solutions for 30 years. By leveraging our know-how across several industries, we continue to innovate “best practices” which allows us to drive efficiencies into our process. This distinguishes ACTIA from the competition and offers our customers an unparalleled competitive edge.

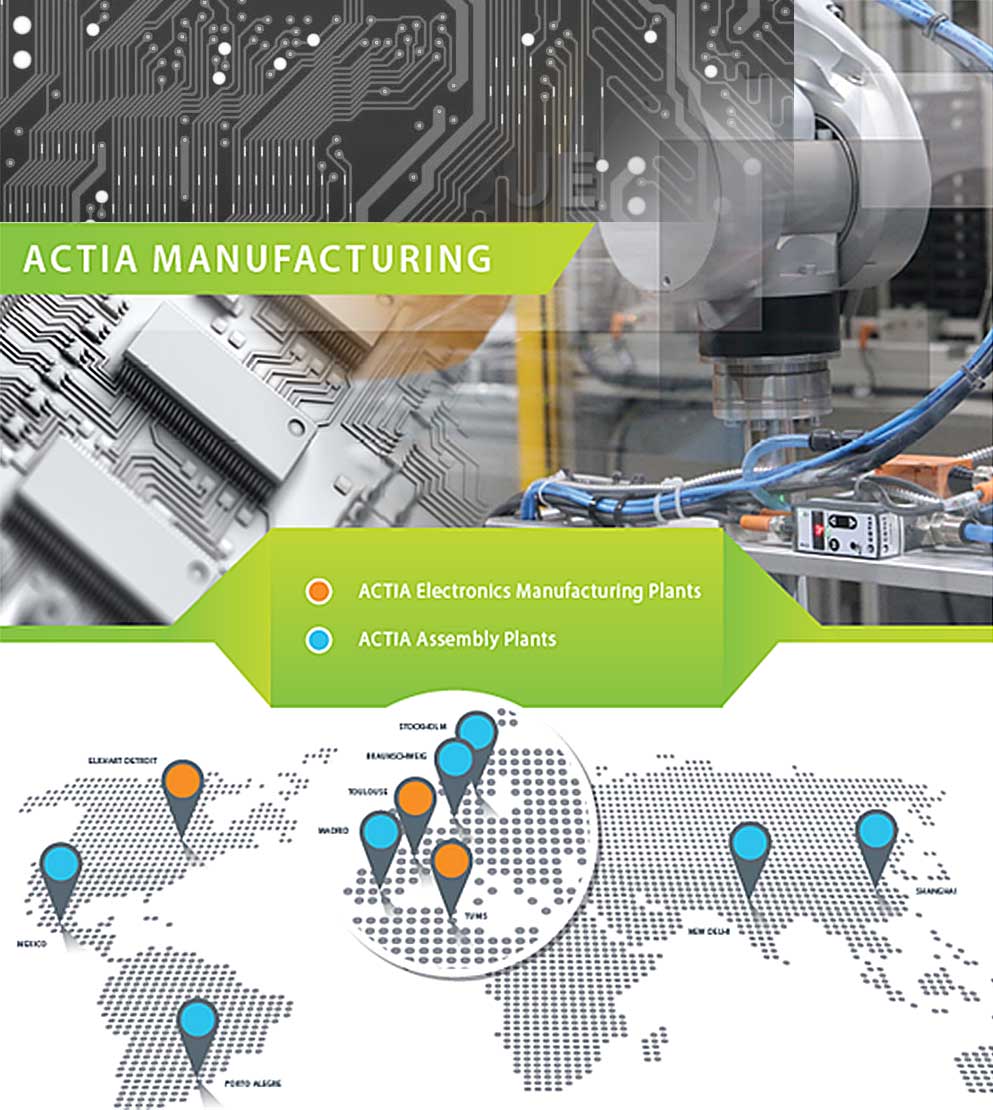

ACTIA Group offers Electronics Manufacturing and Assembly throughout the world.

- ACTIA France (Colomiers)

- ACTIA Tunisia (Tunisia)

- ACTIA Electronics (USA)

More than 5 million finished products leave the Group’s factories every year deployed over multiple markets.

In addition to EMS/Assembly services, we offer a range of comprehensive service solutions:

- Testing and Test Plan Development

- Material Management

- Obsolescence EOL management

- ECN notification

- PPAP

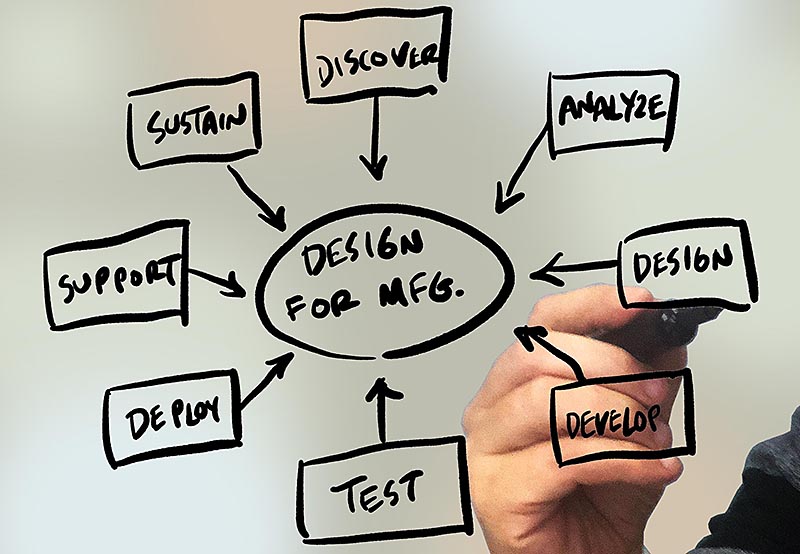

Design for Manufacturing (DFM)

Our expertly trained cross-functional teams are able to support and implement any given design. We review project requirements carefully and create a unique DFM for every project.

Sourcing

ACTIA Electronics has created relationships with suppliers across the globe. By leveraging ACTIA’s global buying power, our customers reap the benefit of negotiated volume pricing through manufacturers and distributors worldwide. Let us quote your PCB assembly today and see how ACTIA's global buying power can benefit you.

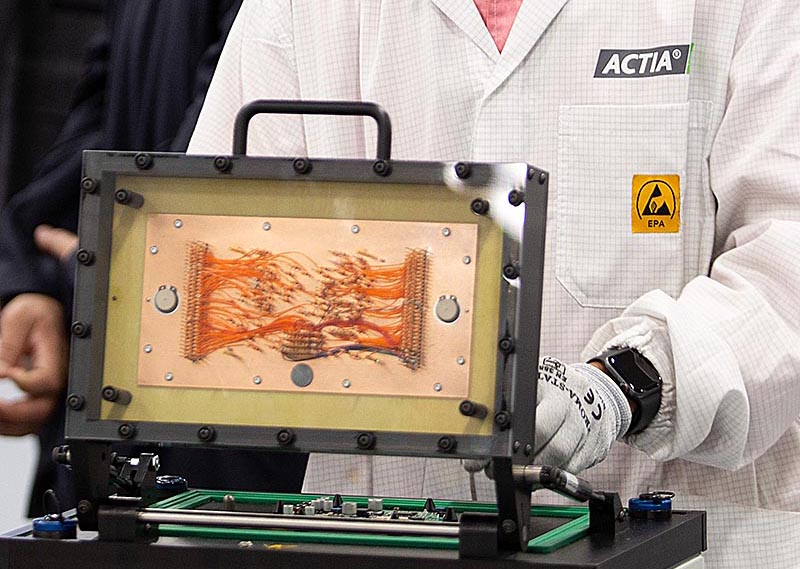

SMT Process to Assembly

Experts in technologies for assembling circuit boards

- Leaded and RoHS reflows

- Adhesive application

- 3D x-ray

- New line wave or selective soldering

- Conformal coating

Integration Cells

A Modular production strategy is used for assembled and tested products. Autonomy to develop assembly cells that integrate final assembly, testing, software downloading and more.

- Faster time to market

- Higher quality

- Reduced costs

Continuous Improvement

Lean Manufacturing and Soft Automation process assure cost-effective solutions to optimize resources and avoid waste.

- Identify opportunities in workflows

- Plan process improvements

- Implement changes

- Review Changes

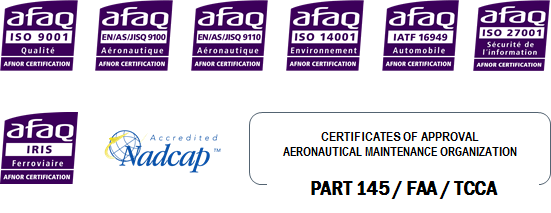

Quality

ACTIA Electronics commitment to quality will increase customer satisfaction by:

- Meeting or exceeding customer specifications and requirements

- On-time delivery

- Providing defect free parts

- Building a quality supplier base

- Enabling our employees to achieve good work the first time and every time

- Establishing a continual improvement process

- Creating a safe working environment for all employees

ACTIA Electronics Knows PPAP

World-class Customer Support

Actia Electronics will meet or exceed your expectations. Every customer relationship is equally important to us and we promise:

- Open Lines of Communication

- The Highest Quality Product

- On-time Delivery

Our highly trained and friendly customer service team will be available every step of the way.

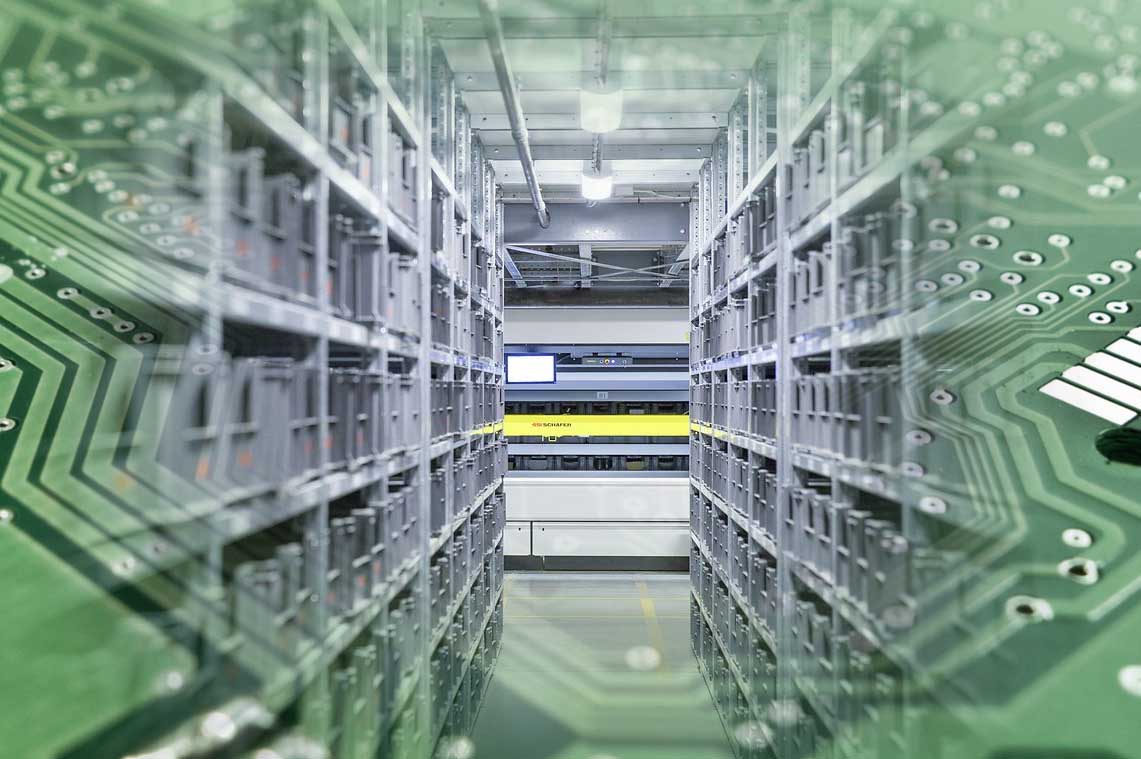

Logistics

Worldwide logistics and supply chain know-how :

transport, customs, regular and ad-hoc flows,

and Vendor Management Inventory.

Direct or Tier 2 delivery from our plants.

ACTIA is certified as an Authorized

Economic Operator (AOE).

ACTIA sites are MMOG/LE approved (Romulus

in 2020) (Level A – 90% – Materials Management

Operations Guidelines / Logistics Evaluation)